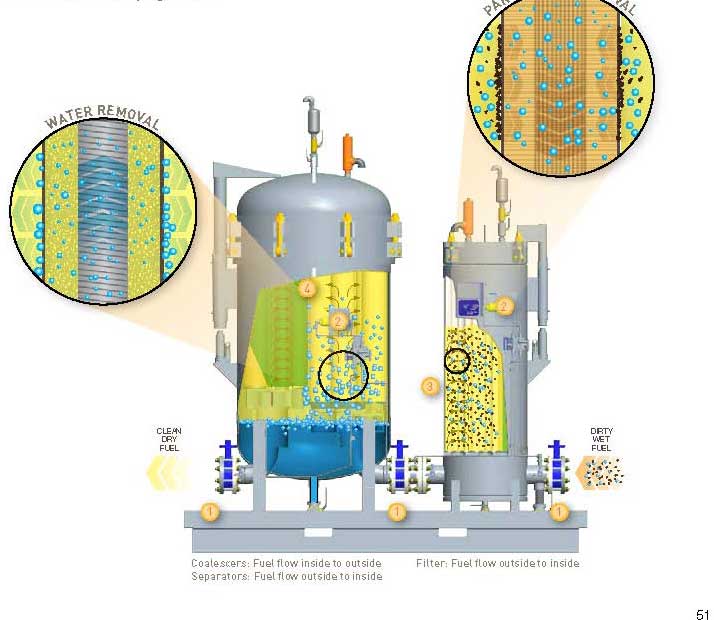

Diesel fuel filtration systems are designed to remove harmful contaminants like particulate and water to improve your equipment’s fuel efficiency, performance and overall reliability. Left untreated, water contamination can lead to microbial growth and cause corrosion to holding tanks and fuel systems.

Diesel Fuel Filtration System Process

The diesel fuel filtration system is a multi-stage filtration process that separates any particulates that could have infiltrated the tank while filling or passing through fuel lines. Fuel filters are essential for any any fuel system, not just diesel, however they are especially important in diesel systems because of the increased viscosity of diesel fuel compared to gasoline. Diesel can often contain more particulates that can lead to damaging the injection pump.

Bulk Fuel Filtration Systems

Filtration Applications

Common applications include polishing fuel for power generation applications, and bulk fuel storage at data centers, hospitals, mining operations, marine terminals & military facilities or any other installation where fuel quality and reliability is critical.

Diesel Fuel Conditioning

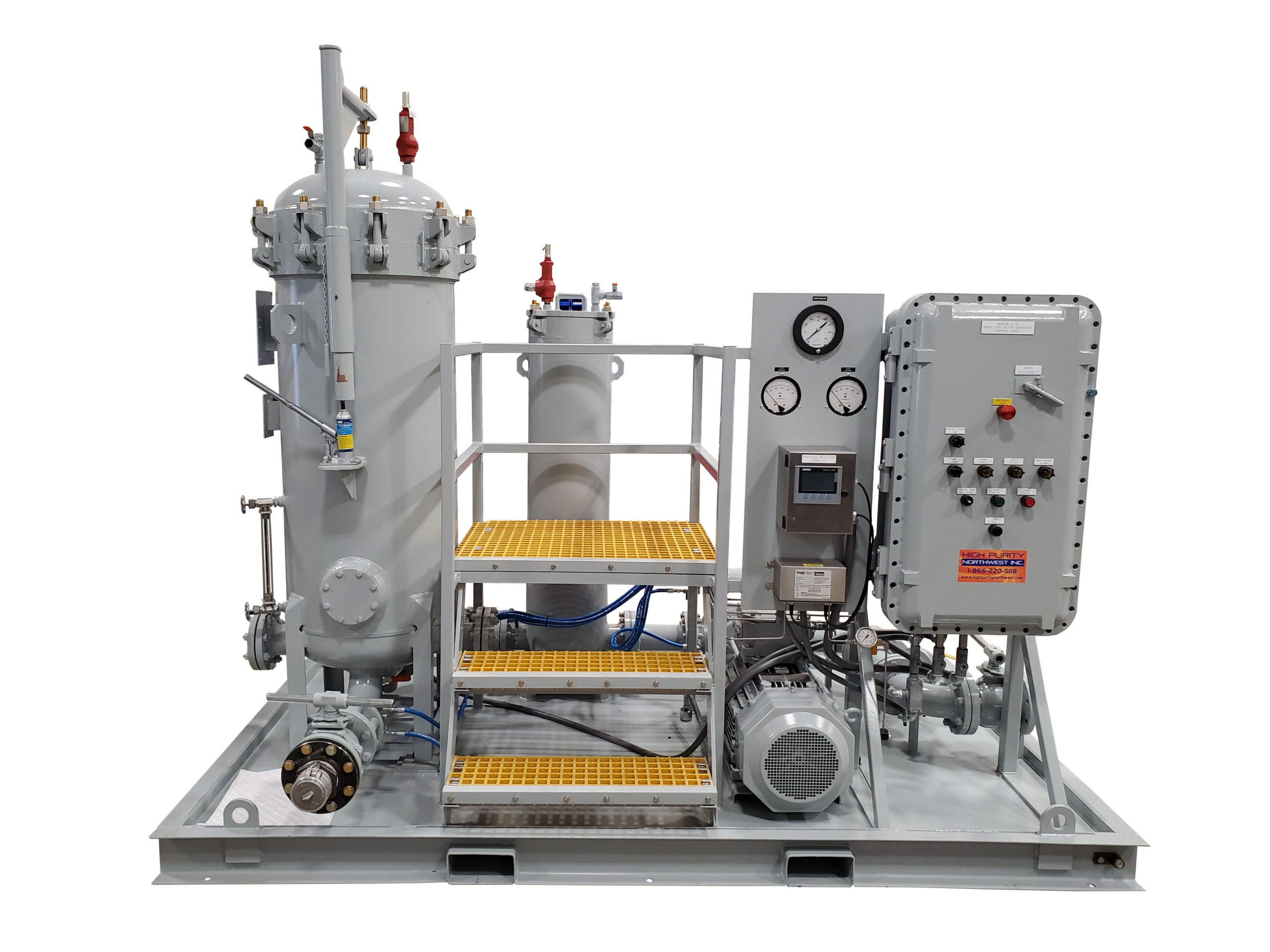

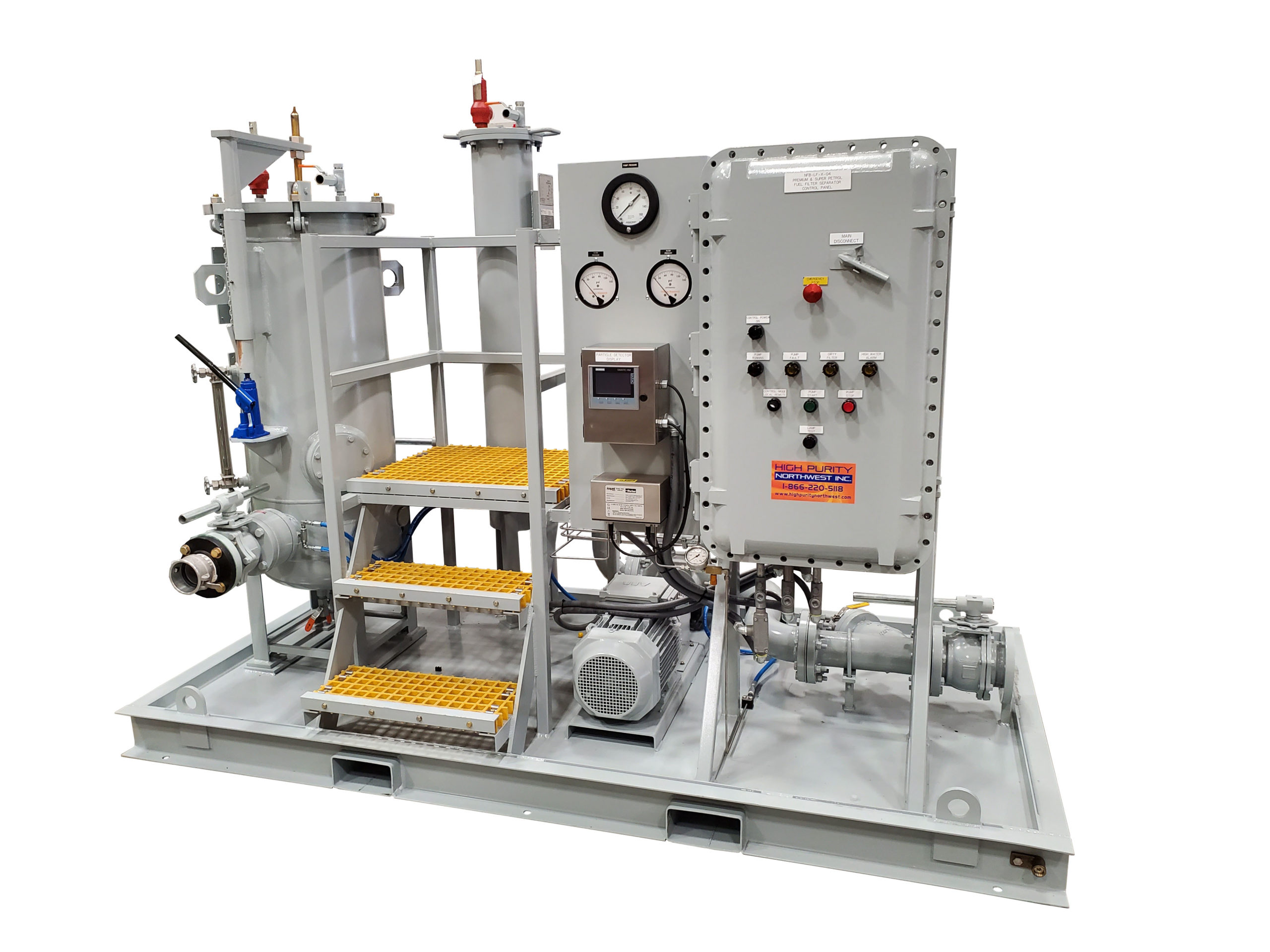

Our diesel fuel conditioning systems are multistage and include filtration and water separation units that utilize the latest technology for fine particle and water content removal. The cut away diagram and photos and videos below show the filtration and coalescing and separation stages of a high flow treatment system. These systems can be in-line and installed on an existing pressurized fuel delivery line or they can be equipped with pumps and controls for recirculation of bulk storage tanks. These systems are available in a wide variety of process flow rates and sizes to meet any industrial or commercial application.

System Features

Our Compact Series family of systems are available with process flow rates from 10-75 GPM. Larger systems range from 100-800 GPM.

Complete custom diesel fuel treatment trailers are available with multiple stages of treatment and chemical injection. These systems are ideal for Fuel Polishing and Cleaning Contractors or companies and agencies with a need for highly capable portable diesel treatment systems.

Common Options

- Laser Particle Counters and Moisture Content Instrumentation to give real time ISO Cleanliness or NAS Cleanliness Codes and moisture content in PPM. These devices can send information to remote locations. They can also be used to stop the system or re-direct flow and return flow from one source to another.

- NEMA 7 Explosion Proof Designs

- On-Board Generator Sets

- Variable Speed Pumps

- Heavy Duty Off Road Capable Trailers

Fuel Polishing Systems

Water and particulate removal solutions for diesel fuel applications using Kidney Loop Systems and Complete In-line Filter Systems

Mobile Diesel Fuel Filtration Systems

Get a Customized Quote for Your Project

Tell us about your project, and we’ll put together a system recommendation and send you a quote for your project needs.