Filtration systems and vacuum dehydrators for removing water and particulate from diesel fuel, hydraulic and lubricating oils

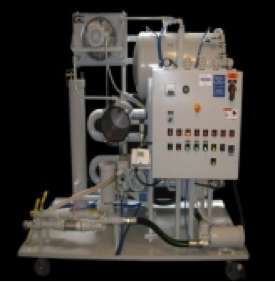

Our Thermo-Vac family of systems are available in a wide selection of process flow rates and are ideal for removing fee and dissolved water and particulates from steam turbine reservoirs, hydraulic systems and oil storage tanks.

Fuel Conditioning Systems

Our FFC Series of systems are available in a wide selection of process flow rates and are ideal for removing water and particulates from diesel fuel. These systems are typically added to process fuel storage tanks. The systems utilize a filter/separator vessel and particulate filter vessel to coalesce the water out of the fuel and remove dirt and other particulate.

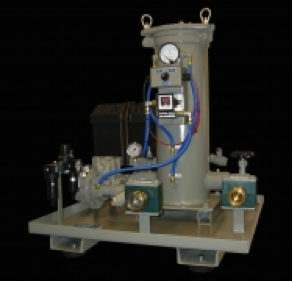

Dedicated filtration systems for oil reservoirs and oil storage tanks

The KL Series of filtration units are also available in a wide range of process flow rates and feature top loading absolute rated filters to insure pristine condition of oils used in sensitive hydraulic servo speed control systems or mail lube oil reservoirs. These systems can be equipped with laser particle counters and moisture in oil sensors to deliver real time ISO cleanliness code and moisture content information.

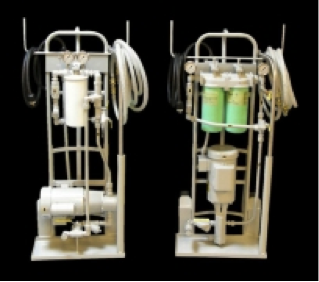

Portable Filter Carts

Our portable FCL series systems can be used for flushing and transferring oils and hydraulic fluids and feature the same absolute rated filters and condition monitoring equipment as our KL and Thermo-Vac systems. These systems are available in simple and economical 5 GPM or 10 GPM hand truck chassis units or much larger hot oil flushing and heating systems with flow rates ranging from 30 GPM to 500 GPM.

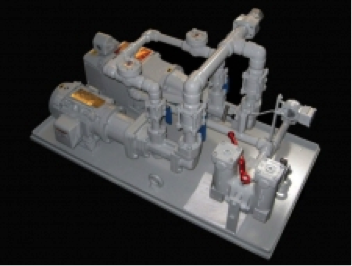

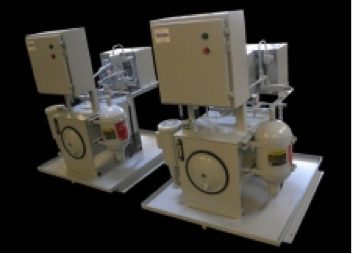

Circulating Lubrication Systems and Hydraulic Power Units

We engineer design and build complete Circulating Lubrication Systems and Hydraulic Power Units to replace aging systems or for new applications within the powerhouse. Our systems can be built to meet the latest API 614 Edition for Lubrication, Shaft Sealing and Oil Control Systems and Auxiliaries.

Transformer & Insulating Oil Degasing and Dehydration Systems

Our easy to use Thermo-Vac TO Series degasses, dehydrates and filters insulating oil with the push of a button. Our fully automated system takes the guess work out of the process. Our PLC starts and stops each component in the proper order. We have made oil purification easy.

The Thermo-Vac TO design maximizes contamination removal by using heat, vacuum level and increased surface area (as well as void space within the vacuum chamber). Our standard system features a single stage 0.5 torr vacuum pump (0.05 torr with High Vacuum Option), stainless steel horizontal vacuum chamber and particulate removal down to 0.5 micron. We have mastered economy with quality components so that performance is maximized and within budget.

These systems are available as stand alone, skid mounted systems or our M.O.P.S, trailer mounted systems for substation maintenance.

Replacement Hydraulic Filters

We use Multi layer Dual-Phase Micro-Glass pleated media is certified to be Beta x[c] = 1000 in accordance with ISO 16889 and Dynamic Filter Efficiency (DFE) testing. Media is supported both upstream & downstream by an epoxy coated c.s. mesh. Our media provides high flow rates, low pressure drop and stable & dependable Beta x[c] rated efficiencies. Our medias range from 2.5u, 3u, 6u, 12u & 25u Beta x[c] 1000 rated efficiencies per ISO 16889 & DFE. With over 150,000 part numbers in our database, we cross all major brands such as Pall, Parker, Hypro, Donaldson, Schroeder, Hycon, PTI, Purolator, Norman and others.

Fuid Storage and Dispensing Systems

Our DTU Oil Storage and Dispensing Systems are ideal for the storage and the precise metered dispensing of lubricants, automatic transmission fluids, antifreeze and coolants, or any other commonly used fluids in industrial applications. These systems help present an organized lubrication room, reduce the possibility of cross contamination and increase fluid cleanliness.

These systems feature all stainless steel construction and built in Absolute filtration. An operator can off load bulk fluids from tankers or drums and set the timer to cycle the oil or fluid through the filter assembly until the desired ISO cleanliness code is achieved. There is also a simple on/off switch used when dispensing. All fluid dispensed passed through the filter assembly on the way to the electronic lube meter gun when in dispensing mode.

These systems feature:

- Capacities from 25 to 3000 gallons

- Parker Filter Assemblies with Absolute rated filters

- Stainless Steel construction and Stainless Steel Plumbing

- Lincoln Hose Reels with Electronic Lube Meter Dispensing Guns

- High Quality Industrial Gear Pumps with built in Pressure Relief

- Dehydration packages

- Laser particle counters

- Moisture in oil sensors

- Mobility Package

Options include:

- Dehydration packages

- Laser particle counters

- Moisture in oil sensors

- Mobility Package

Get a Customized Quote for Your Project

Tell us about your project, and we’ll put together a system recommendation and send you a quote for your project needs.