Lube Oil & Hydraulic System Flushing Services

High velocity oil flushing services remove water, rust, dirt and other harmful contaminants to enhance your hydraulic equipment performance

Our team provides turn-key pre commissioning, periodic maintenance, and post overhaul oil flushing services for circulating lubrication systems and hydraulic systems in industrial applications.

All our systems are equipped with laser particle counters and moisture in oil content meters to give real time ISO or NAS Cleanliness Codes and water content information. At the end of flushing job, a comprehensive report is submitted documenting the oil cleanliness and dryness through multiple methods including third party lab verification.

Our team adheres to strict safety procedures and spill prevention awareness and response and strives to get the work done safely and efficiently during equipment outages, startups, and during or after system repairs or maintenance.

Typical oil flushing jobs include steam, gas and hydroelectric turbine lube oil systems, compressor lube and seal oil systems, paper machines, hydraulic systems, EHC governor systems, or any other industrial or marine lube or hydraulic system where oil flushing and purification is needed.

Completed Oil Flushing & Purification Job Examples:

POWER PLANT APPLICATIONS

U.S. Army Corps of Engineers Lower Granite Dam, Little Goose Dam, & Lower Monumental Dam Main Lube Oil Supply and Return Header Flush and Oil Storage Tank Cleaning:

Our team mobilized to perform back-to-back critical flushing services at these three hydroelectric projects on the lower snake river. These ageing powerhouses lube oil supply lines and oil storage tanks needed vigorous cleaning to ensure the reliability of these large power producing assets. Each project presented unique logistical challenges and meticulous attention to safety while working in this sensitive marine environment. The job was finished ahead of schedule and the results were better than required by the USACE.

HYDRAULIC SYSTEM APPLICATIONS

U.S. Navy Hydraulic Oil Purification for the U.S.S. Ohio Trident Nuclear Submarine at Puget Sound Naval Shipyard & IMF. High Purity Northwest, Inc. Post Award Conference N4523A18P0819 – Hydraulic Oil Cleaning

High purity Northwest was selected to perform critical oil purification as part of a complete hydraulic system flush for this very important military asset. The hydraulic systems had been contaminated with water and particulates and all the fluid on board the vessel was in need of extensive dehydration and fine filtration. Our specialized systems and processing tanks were used to quickly restore the fluid to much cleaner and drier than navy specifications. Time of processing was critical in this application as there were large amounts of fluid needing to be processed in a short period of time. Our team was on station during this critical maintenance and repair period and tens of thousands of gallons of hydraulic fluid were processed.

Puget Sound Naval Shipyard & Intermediate Maint. Facility

Lower Baker Dam Powerhouse Water Intake Gate Hydraulic System Flush

Our team was selected to perform high velocity hydraulic system oil flushing prior to commissioning of new systems at Puget Sound Energy’s Lower Baker Dam. The job presented challenges as space for equipment was very limited and we needed to operate all of our systems from the transportation trailers. The job included flushing of the new systems until cleanliness codes of 16/14/10 or better per ISO 4406 Standards were met. The project also included delivery of 1500 gallons of filtered new oil into the new reservoir.

US Army Corps of Engineers Lake Washington Ship Canal Navigational Locks Hydraulic Systems

High Purity Northwest Inc was selected by the US Army Corps of Engineers, Seattle District to perform a service of the main hydraulic systems for the large locks at the Lake Washington Ship Canal Ballard Locks. The job had a time window as the Ballard Locks are a critical passageway for commercial vessel traffic in the area. The large locks hydraulic systems could only be taken offline during the annual maintenance shutdown and could only be down for two weeks. The job is also in an extremely environmentally sensitive marine area, so equipment containment and zero oil spillage were of the utmost importance.

The job summary included complete drainage of the hydraulic systems, cleaning of the hydraulic reservoirs, replacement of all of the hydraulic hoses, inspection of all of the hydraulic components, complete fill and purge of the system with new oil and then flushing of each circuit to an ISO 4406 Cleanliness code of 17/15/12 and also moisture removal to less than 100 PPM residual water content.

The job had many logistical and environmental protection challenges, but the High Purity Northwest team completed the job ahead of schedule and we exceeded all of the performance specifications set forth by the USACE.

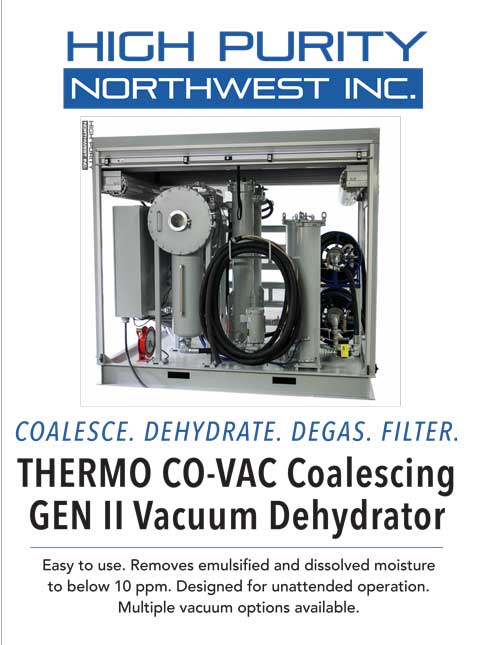

The equipment used included the latest technologies in vacuum dehydration, high velocity oil flushing, filtration, and oil heating & cooling.

STEAM & GAS TURBINE APPLICATIONS

Nippon Paper New Power Plant GE Turbine Pre-Commissioning Hot Oil Flush

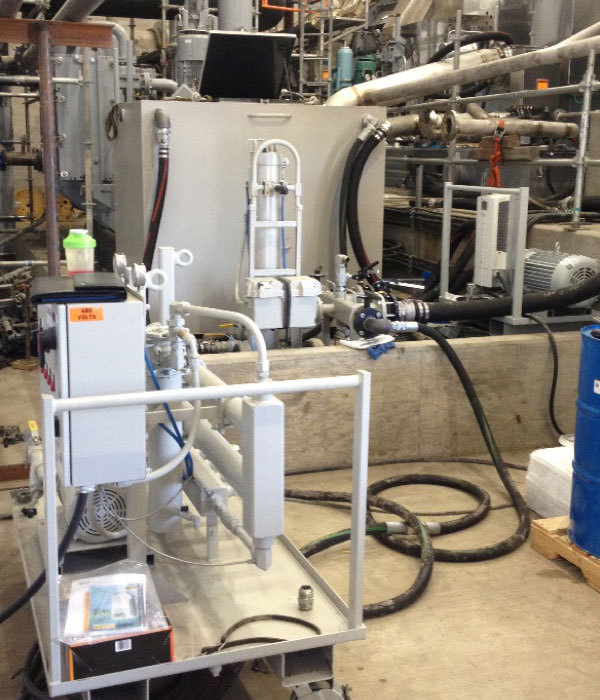

Our Team was chosen to perform a complete lube oil system flush for a new steam turbine at a major paper manufacturing plant. General Electric required the entire lube oil system to be flushed to specific and stringent ISO Cleanliness Codes and for this to be formally documented prior to commissioning of the new plant. Our flushing and filtration systems and specially designed flushing tank shown in the photos of the work site below are key components in reaching the target cleanliness levels fast.

BENEFITS OF OIL FLUSHING

- Rids of Sludge and Debris

- As engines are used, sludge and other deposits develop, causing a decrease in performance. Regular oil flushing helps to rid of these buildups and enhance performance.

- Lengthens Engine Lifespan

- Engines that are cleaner tend to be more durable and last for longer periods of time. To avoid deterioration over time, getting your engine cleaned through oil flushing services is the best option.

- Lessens Oil Utilization

- When oil is older and has more dirty qualities, it often takes more oil consumption to make an engine run. Through oil flushing services, you can put new, cleaner oil into your engine that will not need to consume as much oil to run.

- Enhances Start-Up Time

- By keeping your oil clean through oil flushing, starting up your engine becomes a lot smoother. This can help especially in colder circumstances.

PETROLEUM REFINERY LUBE & SEAL OIL SYSTEM FLUSHING

Gas compressor lube and seal oil flushing and chemical cleaning & cooling water lube system flushing:

The images below show our systems at work at a large American petroleum refinery. The lube and seal oil systems and related plumbing had significant varnish deposits and were coated with contaminants related to decades of operation and deferred maintenance. We performed a chemical cleaning and high velocity oil flush and reservoir cleaning that left all of the stainless-steel surfaces of the system pristine and looking like new.

Get a Customized Quote for Your Project

Tell us about your project, and we’ll put together a system recommendation and send you a quote for your project needs.