System Uses

Thermo-Vac Systems – The Complete Solution for Oil Purification

- These robust oil vacuum dehydrators are designed to rapidly remove free, emulsified and dissolved water as well as dissolved gases, fine particles and varnish.

- They are used to greatly enhance the reliability of plant equipment by the removal of harmful moisture and particulates and are key in mitigating un-planned downtime

- These oil purification systems feature Absolute rated (BETA 1000 per ISO 16889) filters both upstream and downstream of the vacuum dehydration process.

- The Thermo-Vac family of oil purification system equipment is available in a wide range of sizes with process flow rates from 2.5 GPM to 100 GPM.

- These systems are designed to reach and maintain dryness levels to less than 20 PPM and ISO cleanliness codes of 13/10/8 or better are common.

- Thermo-Vac Systems are available with Optional Varnish Removal Sections.

- These systems include Laser Particle Counters that display real time ISO 4406 Cleanliness Codes and Moisture Content information.

- Thermo-Vac Systems are often supplied with options including specially designed on-board batch processing tanks.

- All our oil purification systems are offered in Class 1 Div 2 or Class 1 Div 1 (NEMA 7) Explosion Proof Electrical Classifications

- Please see attached PDF download or print literature for more features and options.

- We have design flexibility where custom features or footprint dimensions are required.

Standard Features

- Low watt density oil heaters for rapid oil heating without thermal damage

- Automatic operation: The controls of the system allow it to safely run unattended for long periods. Precise temp and vacuum settings and automatic start-up and shutdown sequences make this system safe and very easy to use. The Laser Particle Counter option allows the system to stop or transfer flow when target dryness and cleanliness have been achieved.

- Remote monitoring and control.

- Automatic foam detection and elimination.

- Phase reversing switch makes moving the system to various power connections easy.

Available Options

- Thermo-Vac Systems are available with Varnish Removal Filters

- These systems are also available with oil condition monitoring options that give real time ISO 4406 cleanliness code and moisture content information. The Thermo-Vac Systems are often supplied with options including specially designed on-board batch processing tanks, coalescing vessels for rapid free water removal and adsorptive media vessels for acid removal.

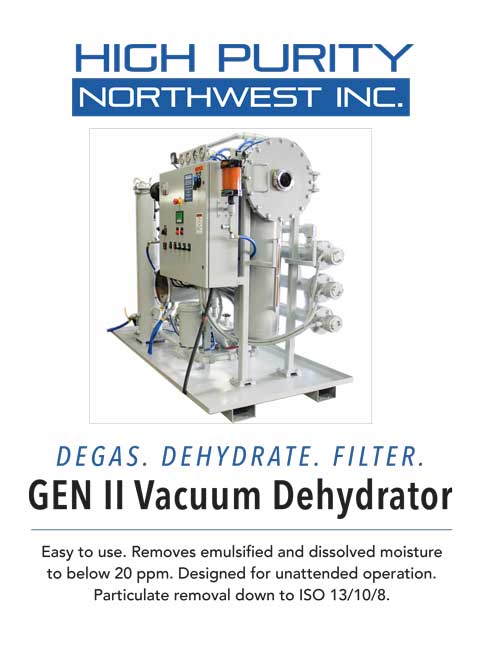

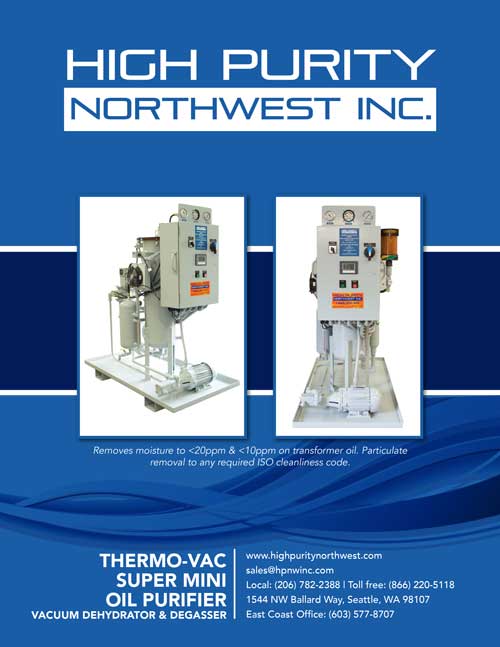

- Please download our PDF product literature for the GEN II and Super Mini systems, for more features and options.

- We have lots of flexibility where custom features and dimensions are required.

System Examples

This is our smallest Thermo-Vac System with a flow rate of 2.5 GPM. It features all of the same components of our larger systems but scaled down for use with small hydraulic reservoirs and oil reservoirs. We offer a specialized version of this system for use with Skydrol and other Phosphate Ester Fluids. This photo shows the system with an optional on-board processing tank. Please download our PDF literature for more details of the TV Super Mini.

These two systems are medium sized systems with flow rates of 20 & 30 GPM. They are available in portable or skid mounted configurations and are ideal for use in hydro-powerhouses, and steam turbine lube oil reservoirs. They are also a common size for use in paper mills and steel mills. Please download our PDF literature for more info on the Thermo-Vac Gen II systems.

This is a very powerful 100 GPM Thermo-Vac degassing system. It has high volume, deep vacuum capability. This system is ideal for applications where a high rate of degassing and extreme dryness is applicable. This type of system is perfect for transformer oil reclamation or any high volume application where purity is critical.

This High Purity Northwest Inc Thermo-Vac System was built specifically to replace an aging centrifugal type system in the oil storage room at a major hydro-electric power house. The system was constructed with a custom footprint and component orientation so that it easily fits into the location where the old system was. This system has VFDs to control the process flow rate from 5 GPM up to 60 GPM and is designed to process dirty oil batches ranging in size from 5,000 to 20,000 gallons at a time. The system features an Allen Bradly control system and in-line laser particle counter to provide real time ISO 4406 Cleanliness Codes and moisture content information. It also has large capacity Absolute rated filters upstream and downstream of the vacuum dehydration process. This system features rotary screw oil pumps and welded stainless-steel piping. The system has all of the safeguards necessary for unattended operation and has an automatic start-up and shutdown sequence to ensure equipment reliability, safety and thermal protection of the treated oil.

The U.S. Bureau of Reclamation Grand Coulee Dam, the largest power plant in the United States and the second largest hydro power plant in the world, selected High Purity Northwest Inc to build a new state of the art oil purification system to purify turbine oil. This system was built with a custom footprint and component orientation to fit in the exact spot where the old oil filtration system was. This system replaced an aging Alpha De Lavalcentrifuge and filter press.

Get a Customized Quote for Your Project

Tell us about your project, and we’ll put together a system recommendation and send you a quote for your project needs.