Oil Filter Carts & Systems

Oil filter carts are designed to provide a portable mode of off-line kidney loop filtration, flushing and fluid transfer. Our oil filter carts and kidney loop filtration systems are rugged industrial systems for use where cleanliness of oil is critical. These oil filtration systems feature BETA 1000 Absolute rated micro-glass filter elements and Adsorptive Ion Exchange Resin Media Filters for Varnish Removal.

Particulate Filters are available in a variety of micron retention ratings to meet any target ISO 4406 Cleanliness Code requirements and for any industrial system.

Common applications include lube oil and hydraulic fluid reservoirs, gear box filtration, phosphate ester EHC systems, Skydrol filtration, governor speed control hydraulic systems and mobile equipment hydraulics. These oil filtration systems are an essential part of plant reliability and the reduction of unplanned downtime. They greatly extend the life of any rotating, reciprocating or hydraulic equipment.

Filter Cart System Uses:

- To remove harmful particulates, water and varnish

- Filtering new and used oil

- Transferring filtered oil

- Cleaning & transferring lubricants

- Draining used oil

- Contamination control

Standard Features

These systems are available in a variety of flow rates ranging from 2 GPM to more than 500 GPM and standard features include TEFC motors, positive displacement gear or screw pumps with integral pressure relief, top loading filter assemblies, color coded differential pressure gauges to monitor filter life, NEMA 4 electrical enclosures and a two-part epoxy paint coating.

Single phase or three phase electrical connections for any electrical service available throughout the world.

Available Options

- Laser particle counter with moisture content. This device displays and transmits real time ISO Cleanliness Codes and moisture content information. This instrument can be used to start, stop or transfer flow between two or more reservoirs

- Varnish removal with adsorptive cellulose or Ion Exchange Resin Technology to remove sub-micron contaminants and soluble varnish from oil and varnish coated components in any system

- Water absorbent filter elements

- Explosion proof Class 1 Div 1 (NEMA 7) or Class 1 Div 2 rated systems

- Low watt density oil heaters

- Phosphate Ester or Skydrol compatible materials of construction

- Variable flow rate pump controls

- Hose reels

- Custom footprint and component layout

Systems We Offer

Portable Systems

The system shown above at the left is a very simple yet capable 5 GPM kidney loop filtration system with Absolute Rated Micro-Glass Filter Media and industrial on/off switch. The system in the center image is a two stage, XP Rated, highly efficient particulate and Varnish Removal System with Ion Exchange Resin Media Technology. The system above and to the right is a two-stage system with a micro-glass absolute rated element and a second stage adsorptive cellulose media element for semi-soluble sludge and water removal.

These two images show medium capacity systems with multiple stages filtration and heat. The system on the left is a compact hand truck style system with an aluminum chassis and three stages of filtration. The system on the right processes at 25 GPM and has 32KW oil heaters and a leaser particle counter.

Light Weight Aluminum Portable System

This very capable yet light weight system has massive dirt holding capacity and is capable of extremely fine filtration. It accepts a variety of filter elements and media types to fit nearly any application. It operates from a 230V single phase circuit and includes a 7KW oil heater and moisture in oil monitor that displays real time relative saturation levels. This system is ideal for applications that dictate high capacity and performance in areas where heavy systems may be difficult to maneuver.

High Flow Portable Flushing Systems

The system at the left is a 60 GPM two stage system. The system shown in the center above is a 50 GPM two stage, portable flushing system and includes a laser particle counter. The system on the right is relatively compact but has a processing filtration flow rate of 250 GPM and multiple discharge ports and a laser particle counter.

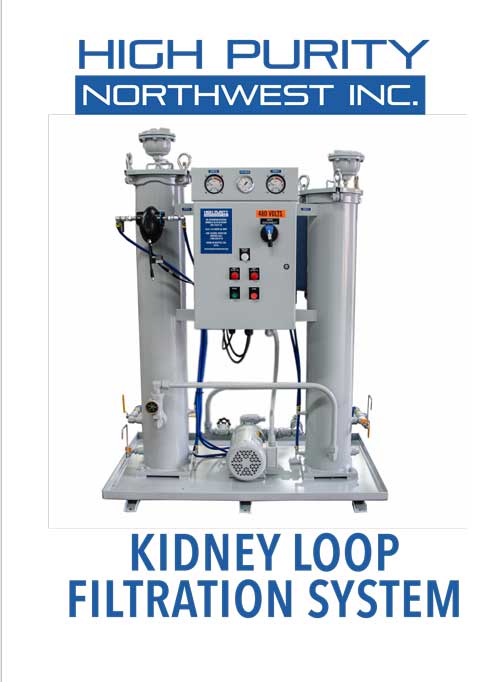

Small Stationary & Kidney Loop Filtration Systems

The system shown above at the left is a very simple yet capable 5 GPM kidney loop filtration system with Absolute Rated Micro-Glass Filter Media and industrial on/off switch. The system in the center image is a two stage, XP Rated, highly efficient particulate and Varnish Removal System with Ion Exchange Resin Media Technology. The system above and to the right is a two-stage system with a micro-glass absolute rated element and a second stage adsorptive cellulose media element for semi-soluble sludge and water removal.

Two Stage High Efficiency Particulate and Varnish Removal System

Medium & High Capacity Stationary Systems

The system shown above at the left is a high capacity system that is ideal for keeping lube oil in large reservoirs in pristine condition. It features our 639 series high capacity filter placed on a 45 degree angle for ease of filter changes and a lower overall profile. The system shown in the center image is a two stage high capacity system that accepts a wide variety of media options toa address nearly any contamination issue. The system above and to the right features a high capacity filter and low watt density oil heaters. This system is designed to keep oil in medium to large reservoirs extremely clean and within a few degrees of a desired set point temperature. This system is also equipped with a laser particle counter that displays and transmits real time ISO or NAS Cleanliness Codes and moisture content.

Get a Customized Quote for Your Project

Tell us about your project, and we’ll put together a system recommendation and send you a quote for your project needs.