Diesel generators are the backbone of data center resilience. When grid power fails, generator performance determines whether operations continue or shut down. Diesel fuel filtration in data centers plays a direct role in that outcome. Fuel that looks clean can still contain contaminants capable of disabling an entire backup power system at the worst possible moment.

As data centers increase load density and uptime requirements, fuel cleanliness standards continue to tighten. Fuel polishing and filtration are no longer optional maintenance tasks. They are a core reliability strategy.

Diesel fuel stored on site faces long dwell times. In many data centers, fuel sits unused for months or years between generator run events. Over time, several issues develop inside storage tanks:

- Water accumulation from condensation

- Microbial growth at the fuel water interface

- Oxidation and fuel degradation

- Sediment and particulate buildup

- Corrosion byproducts from tanks and piping

These contaminants move downstream during generator startup. Without proper filtration, they clog injectors, damage fuel pumps, and cause incomplete combustion.

The Role of Diesel Fuel Filtration in Data Centers

Diesel fuel filtration in data centers focuses on removing solid and liquid contaminants before fuel reaches the generator engine. Effective filtration protects system components and ensures predictable generator performance during emergency events.

Key benefits include:

- Reduced risk of generator failure during load acceptance

- Extended life of injectors, pumps, and fuel system components

- Improved combustion efficiency and emissions performance

- Compliance with generator manufacturer fuel cleanliness requirements

Filtration systems address particulates and free water. Polishing systems go further by conditioning the fuel itself.

What Is Data Center Diesel Fuel Polishing?

Data center diesel fuel polishing is a continuous or periodic process that cleans stored fuel inside the tank. Unlike point-of-use filtration, polishing removes contamination before it reaches the generator supply line.

Fuel polishing systems typically remove:

- Free and emulsified water

- Microbial contamination and biomass

- Oxidized fuel compounds

- Fine particulates below injector tolerance

Polishing stabilizes fuel chemistry and maintains cleanliness standards even during extended storage cycles.

Why Fuel Polishing Prevents Downtime

Generator failures during outages often stem from fuel issues rather than mechanical defects. Common failure modes include clogged filters, restricted fuel flow, injector fouling, and fuel starvation under load.

Fuel polishing reduces these risks by maintaining consistent fuel quality across the entire storage system. Clean fuel supports faster generator startup, smoother load transitions, and sustained runtime during prolonged outages.

For data centers operating at high availability tiers, this reliability margin matters.

Filtration Standards and Manufacturer Requirements

Most generator OEMs specify fuel cleanliness targets based on ISO cleanliness codes and water content thresholds. Fuel delivered to a data center may initially meet specifications, but storage conditions can quickly alter those properties.

Routine diesel fuel filtration and polishing help align stored fuel with manufacturer guidelines over time. This reduces warranty risk and supports documented maintenance programs, which are required for audits and compliance.

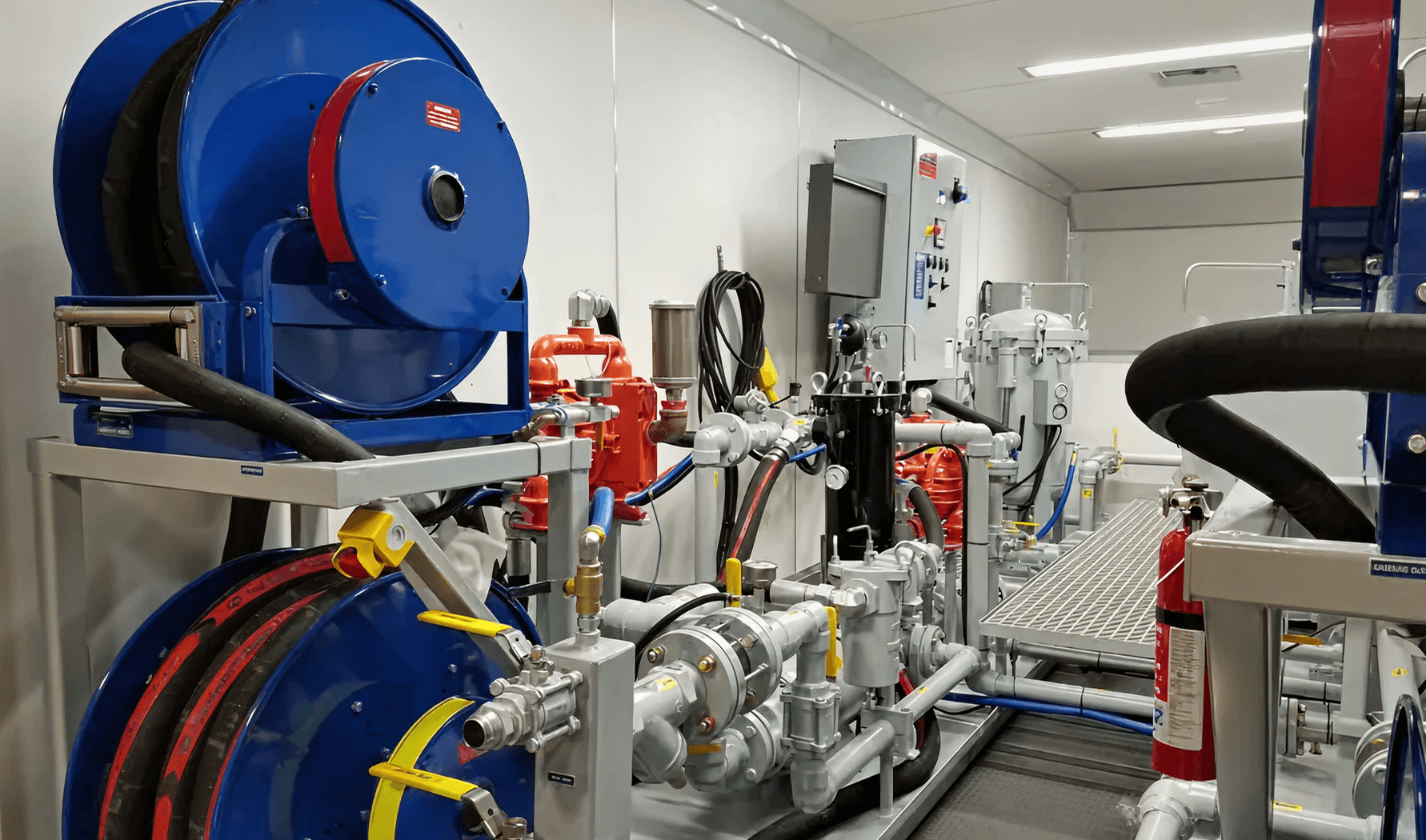

Designing a Diesel Fuel Filtration Strategy for Data Centers

An effective strategy combines multiple layers of protection:

- Bulk fuel polishing to maintain tank cleanliness

- Inline filtration at fuel transfer and day tank fill points

- Final filtration at the generator inlet

- Routine testing for water content, particulates, and microbial activity

System design should reflect tank size, generator load, redundancy requirements, and runtime expectations.

When Data Centers Should Schedule Fuel Polishing

The frequency of fuel polishing depends on environmental conditions and operational patterns. Common triggers include:

- Long-term fuel storage exceeding six months

- Detection of water or microbial growth during fuel testing

- Generator filter clogging or pressure drop alarms

- Before commissioning new generators or expanding capacity

Proactive polishing costs far less than emergency response during an outage.

Talk With a Diesel Fuel Filtration Specialist

High Purity Northwest provides diesel fuel filtration and polishing solutions designed for mission-critical environments. If generator reliability is a priority, maintaining fuel cleanliness should be part of the plan.

Contact High Purity Northwest to discuss diesel fuel filtration in data centers and build a fuel maintenance strategy that supports uptime when power loss occurs.

| Contact Us Today |

Frequently Asked Questions

What contaminants are most common in data center diesel fuel?

Water, microbial growth, oxidation byproducts, and fine particulates are the most common contaminants found in stored diesel fuel.

How often should data center diesel fuel be polished?

Many facilities schedule polishing annually or semi annually. High humidity environments or long storage intervals may require more frequent service.

Is filtration alone enough for stored diesel fuel?

Filtration protects downstream components but does not address contamination already present in storage tanks. Fuel polishing is required to clean and stabilize stored fuel.

Can poor fuel quality cause generator failure even if maintenance is current?

Yes. Clean mechanical components cannot compensate for contaminated fuel. Fuel quality is a primary factor in generator reliability during outages.

Does fuel polishing interrupt data center operations?

Fuel polishing systems are designed to operate without disrupting generator availability. Most systems clean fuel while generators remain in standby.

Comments are closed.